PROCESS

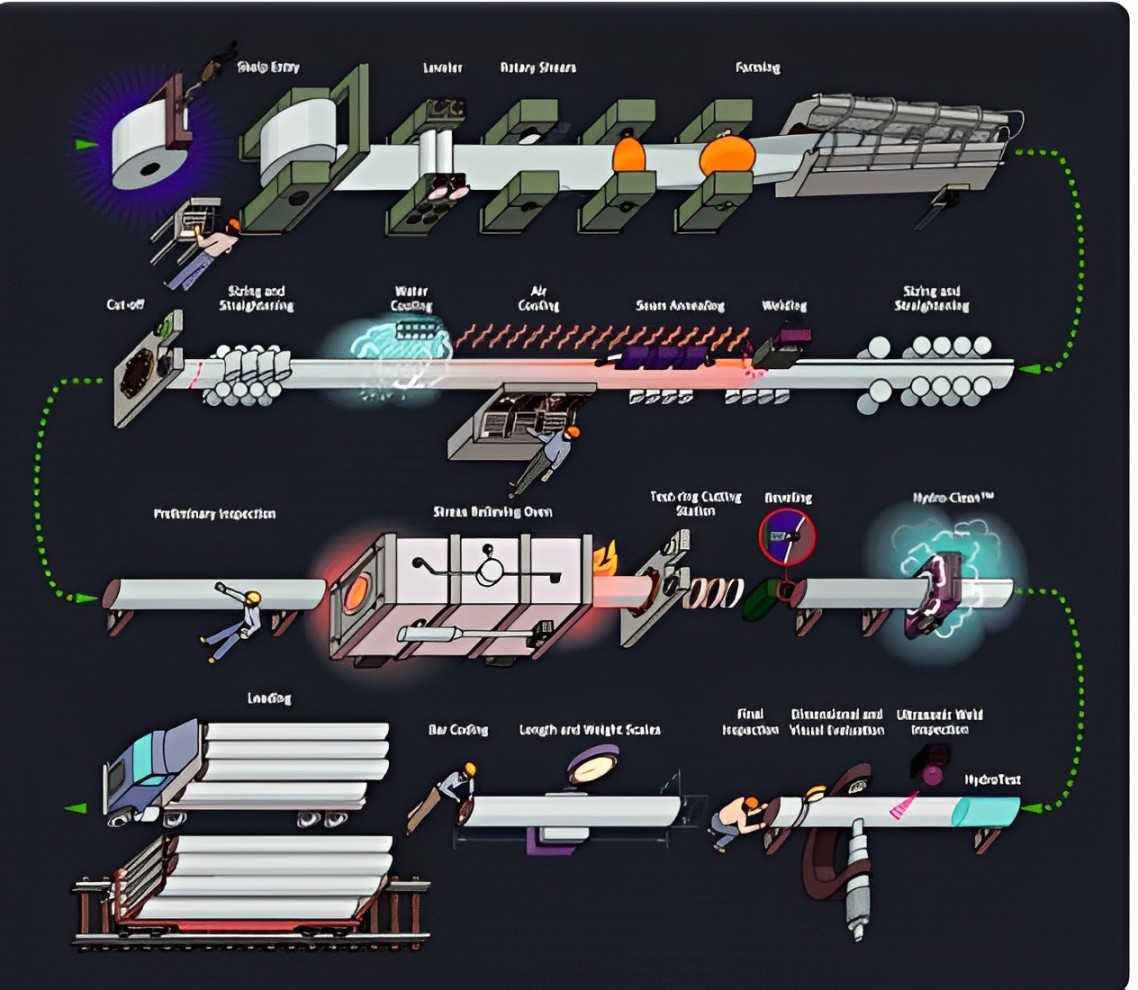

The Manufacturing Process

ERW is a process where strip edges are mechanically pressed together and welded. The heat for welding is generated by the tubing through shoes which acts as sliding contacts. An induction coil can also be used with the high frequency current to induce current in the edges of the strip (induction welding)

Welded Line Pipe is not commonly manufactured by the Electric Resistance weld ERW process. The manufacture of welded line pipe by the ERW process begins with coils of hot rolled sheet steel which are cut by a slitting machine into stripes of precise width needed to produce a desired diameter of pipe. The slit coils are fed into the pipe/tube mills which cold -from the flat ribbon of steel into a tubular clynder by a series of tapered forming rolls. The product is then welded along the joint axis through ERW.The welded tubes then passes under a tool that remove the outside flash reasulting from the pressure during welding. Inside flash may also be remove likewise by cutting tools. The pipe is then subjected to such post weld heat treatment of the welded seam only or treatment of the full cross-section of the pipe to accurate diameter tolerance. The product is cooled and then cut at the end of the pipe mill by a flying shear or saw.

Quality Policy

The Company Management and Employees are fully engaged in achieving the objectives of the Quality Policy, the compliance, and achievements in terms of services delivered are continuously reviewed in order to improve the management system in line with the requirements of ISO 9001.